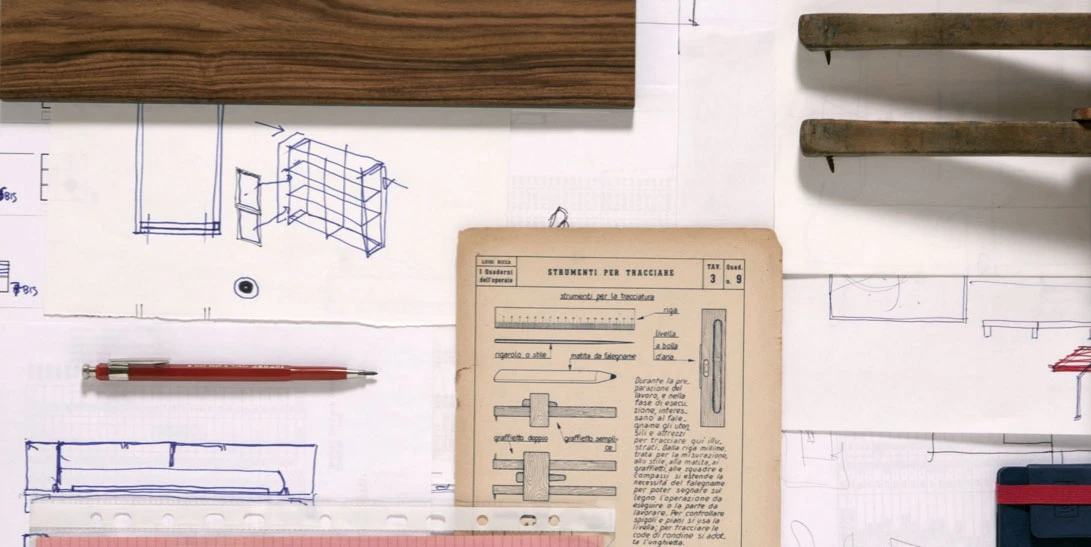

Porro was founded in Brianza, the traditional birthplace of Italian quality furniture. In the heart of this area, in the small town of Montesolaro of Carimate, the brothers Giulio and Stefano Porro, established in 1925 their first workshop dedicated to the production of old-style pieces of furniture produced for the newborn Milanese bourgeoisie.

The transition to second generation of Porro family, with the cousins Carlo, Arturo and Silvio, marked the turn to Modern style in the 50's, also thanks to the long and successful collaboration with the architect Giulio Moscatelli, who in 1955 designed the new workshop next to the family house.In the 60's the transformation in a real industry needed a new productive pole, opened in 1968.

Since its very beginning with some of the main Italian designers, such as Bruno Munari, who in 1966 was entrusted with the design of the corporate logo. From him came the idea of transforming to two Os of the name Porro into two screws seen from above, thus including in the symbol of a woodworking company its most representative working tool.

Since the mid eighties, when the third generation joined the company, the cousins Lorenzo, Fabio, Giovanni e Danilo Porro, design has become the driving force: the partnership with Piero Lissoni, art director since 1989, started right in that period. During the years, he has designed some of the company’s flagship products such as the table Ferro (1994), which is still a bestseller, a sculptural item that perfectly embodies the clean design of the brand.

The attendance to the Furniture Exhibition of Cologne, the cooperation with the German designers Wolfgang Tolk and Werner Aisslinger and the entrance in the German market, are the first steps of a coherent project of internationalization, which strengthens in the 90's, with the creation of an international network of sale agents and the participation to exhibitions on the 5 continents.

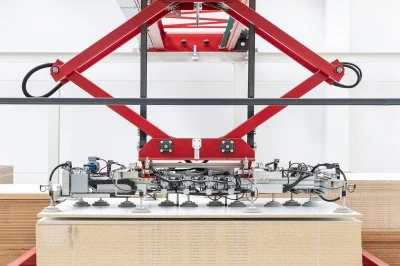

Among the targets of the new millennium, the enlargement of the manufacturing pole in 2000 with the building of a new warehouse of 14 thousand square meters and the opening in 2004 of the first mono-brand shop in via Durini 15, Milan, , moved in via Visconti di Modrone 29 in 2023.

The subsequent cooperation with external designers, among whom Christophe Pillet, Jean Marie Massaud, Front, Alessandro Mendini, Soda Designers, GamFratesi, Gabriele e Oscar Buratti, Nao Tamura, further enhanced Porro catalogue: an all-round offer characterized by many designs, different sensitivities but with a consistent image and the ability to meet the most demanding requirements together.

In 2014 Maria Porro, 4th generation of the founding family, enters the company. She is the current head of marketing and communication of Porro S.p.A., the historical brand of Italian design founded by her great-grandfather Giulio back in 1925, with the energy typical of the new generations and priority attention to sustainable development.

This direction is further consolidated by the arrival of Maria's cousins: Giovanni Porro, coordinator of the management and quality system, Giulio Porro, procurement specialist, and Beatrice Porro.

Since 2017 Porro is partner of Fondazione Altagamma, the institution that gathers companies of the highest cultural and creative Italian industry promoting Italian excellence, uniqueness and lifestyle in the world.

Today Porro Industria Mobili counts on the cooperation of more than 100 employees and over 600 retailers across the globe, with exports account for 70% of turnover.